CABINET CONSTRUCTION

What makes Handmade Kitchens Direct cabinets better than the rest? Please study our cabinet construction to understand how we make our cabinets and see the quality details and fitments we incorporate into every one of our cabinets. Then compare with our competitors. When we say with Handmade Kitchens Direct you get “The Best For Less”, we really do mean it!

HOW WE MAKE OUR CABINETS

Whereas other in-frame manufacturers give you a thinner 10mm back on bases and walls, we build our cabinets with a full 19mm thickness throughout. This gives the cabinet much more strength and rigidity with only a small increase in weight. A worthy upgrade we are sure you agree!

Also, all our adjustable shelving holes have a metal insert in your choice of either a nickel finish or a brass finish. This gives a beautiful look to the interior of the cabinet and allows for a larger 7mm diameter metal shelf support in a matching finish to the inserts. They also have a 100kg weight rating, so you can be rest assured they will never break!

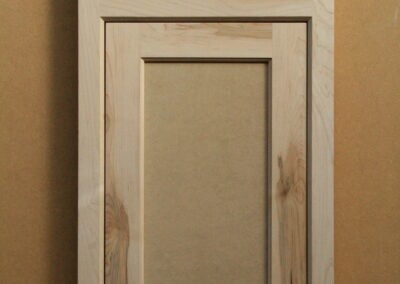

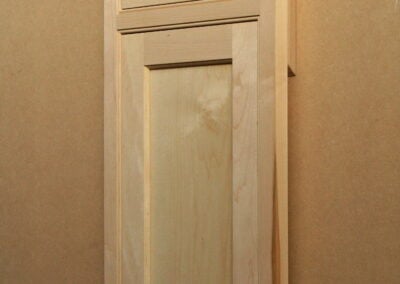

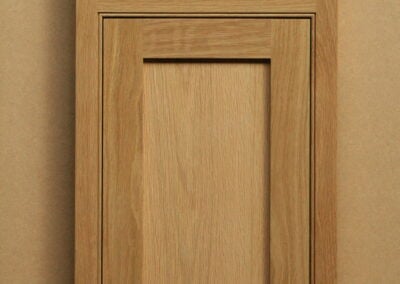

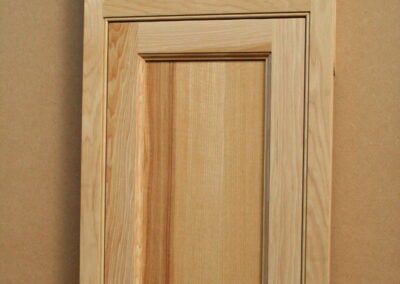

OUR CABINET FRONT FRAMES

All of our front frames are made from 25mm thick solid hardwood of your choice from our offering of 6 different species that includes Hard Maple Paint Grade, Hard Maple, American White Oak, Hickory, Cherry and American Black Walnut. These are jointed under pressure and glued to create a square frame. This is then glued and screwed to the cabinet using hidden pocket screws that are invisible once the cabinet has been installed.

HOW WE MAKE OUR DOORS AND DRAWERS

Our drawer fronts are also available in exactly the same construction, including the top drawer that other manufacturers usually only offer as a flat slab front. We also maintain our drawer front thickness at 25mm, the same as our doors, for a consistent look. Other manufacturers reduce the drawer front thickness down to 18mm due to cost, but we think it’s worth it!

OUR HINGES

How your door is attached to the cabinet front frame is of vital importance to how the door stands up to the test of time. Our standard cabinet incorporates solid brass butt hinges in four different finishes as we believe this is the strongest form of hinging available as we mortise these into the door. We only use high quality solid brass butt hinges in a choice of 4 finishes (polished chrome, polished brass, brushed satin chrome and antique brass). This is a very time consuming way for us to hang the doors, but it means they will not sag over time.

However, we also recognize that some customers want a sleeker contemporary design where you do not see the hinges and so we also offer a concealed door hinge for this look as an option. Again, durability is paramount and therefore we use the German Hettich range of concealed hinges that have a built in soft close action. This option is not normally offered by many in-frame manufacturers.

DOVETAILED DRAWERS

DRAWER RUNNERS